Phased Array & ToFD

Phased Array & ToFD Conventional Ultrasonics

Conventional Ultrasonics Corrosion Mapping

Corrosion Mapping

Phased Array & ToFD

Our Phased Array and Time of Flight Diffraction (TOFD) inspection systems are designed for all industry challenges including:

• Tubing

• Piping

• Pipelines

• Vessels

• Nozzles and Flanges

All our procedures comply with industry codes and standards and we can demonstrate full compliance on thin walled to heavy walled welds. Our solutions are a great fit in all the following industries:

• Oil and Gas Fabrication

• Field Inspections

• Petrochemical Refineries

• Pulp and Paper

• Power Generation

• Structural Applications

Read More• Tubing

• Piping

• Pipelines

• Vessels

• Nozzles and Flanges

All our procedures comply with industry codes and standards and we can demonstrate full compliance on thin walled to heavy walled welds. Our solutions are a great fit in all the following industries:

• Oil and Gas Fabrication

• Field Inspections

• Petrochemical Refineries

• Pulp and Paper

• Power Generation

• Structural Applications

Conventional Ultrasonics

We offer high quality conventional inspection solutions from standard thickness gauging to A Scan inspections.

Conventional Ultrasonics is suited to the following applications:

• W59 Inspection

• Hi volume thickness readings

• Corrosion Assessments

• Corrosion Mapping

• Nozzle and Flange inspection

• Weld inspection

Read MoreConventional Ultrasonics is suited to the following applications:

• W59 Inspection

• Hi volume thickness readings

• Corrosion Assessments

• Corrosion Mapping

• Nozzle and Flange inspection

• Weld inspection

Corrosion Mapping

Ultrasonic C-scans produces a two-dimensional image detailing the location (X and y axis) and size of discontinuities. This method offers numerous advantages over standard ultrasonic thickness measurements. We have include the ability to create a single image that represents the entire inspection area with the ability to generate reports of the images that are produced. Applications include:

• Tank Wall Scanning.

• Pipe wall scanning

• Vessel Shell Inspections.

Read More• Tank Wall Scanning.

• Pipe wall scanning

• Vessel Shell Inspections.

Radiography Inspection

Radiography Inspection Film Digitization

Film Digitization

Radiography Inspection

Gamma radiation sources, most commonly Iridium-192 and Cobalt-60, are used to inspect a variety of materials. The vast majority of radiography concerns the testing and grading of welds on pressurized piping, pressure vessels, high-capacity storage containers, pipelines, and some structural welds.

Our radiography services are geared towards efficiency in high production industries such as fabrication shop and field environments.

In conjunction with traditional radiography we offer close proximity radiography with Selenium sources that significantly reduce the barrier zone ensuring your productivity is maximized.

Read MoreOur radiography services are geared towards efficiency in high production industries such as fabrication shop and field environments.

In conjunction with traditional radiography we offer close proximity radiography with Selenium sources that significantly reduce the barrier zone ensuring your productivity is maximized.

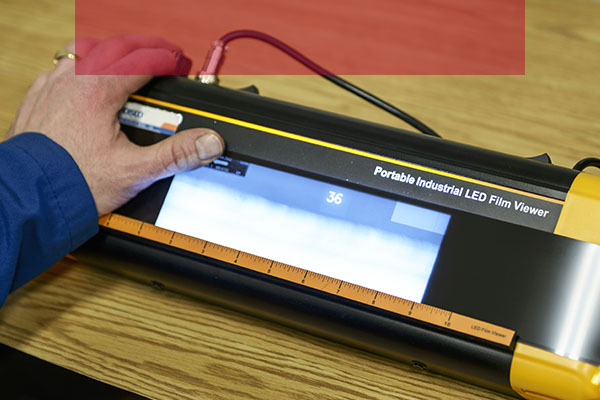

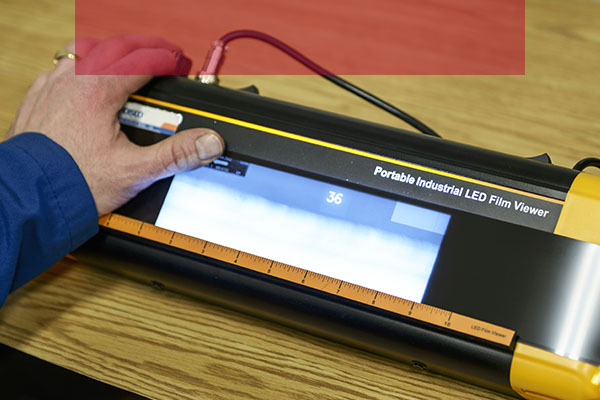

Film Digitization

We offer digitization of your X Ray Film. Our clients use the service to save film electronically and in so doing:

• Preserve image quality.

• Reduce the storage space.

• Share the film images using e mail.

Read More• Preserve image quality.

• Reduce the storage space.

• Share the film images using e mail.

Magnetic Particle & Dye Penetrant

Magnetic Particle & Dye Penetrant Positive Material Testing

Positive Material Testing Ferrite Testing

Ferrite Testing Visual

Visual Hardness Testing

Hardness Testing

Magnetic Particle & Dye Penetrant

Magnetic Particle and Liquid Penetrant Inspection has long been used for the inspection of surface anomalies specifically on and around welds. The techniques cover Ferrous and Non Ferrous materials.

Read More

Positive Material Testing

We provide a fast and accurate material identification and analysis services for a range of metals and alloys including:

• Stainless Steel

• Chromium-molybdenum

• Aluminum

• Cobalt

• Copper

• Magnesium

• Nickel

• Nickel/cobalt

• Titanium

• Zinc and zirconium alloys

Read More• Stainless Steel

• Chromium-molybdenum

• Aluminum

• Cobalt

• Copper

• Magnesium

• Nickel

• Nickel/cobalt

• Titanium

• Zinc and zirconium alloys

Ferrite Testing

In order to guarantee the acceptable ferrite content in the product under inspection, ferrite measurements are performed.

Ferrite measurement is a non-destructive test method that can be performed in the shop or field, that assures the quality of the product without the need of expensive laboratory based destructive test methods.

Read MoreFerrite measurement is a non-destructive test method that can be performed in the shop or field, that assures the quality of the product without the need of expensive laboratory based destructive test methods.

Visual

Quality control weld inspection by CWB certified weld inspectors for both piping and structural steel.

In process weld inspection, visual and NDE.

NACE Coating Inspection quality control.

HDPE Fusion bond welding quality control.

Hydro Testing

Read MoreIn process weld inspection, visual and NDE.

NACE Coating Inspection quality control.

HDPE Fusion bond welding quality control.

Hydro Testing

Hardness Testing

Hardness testing is key to the manufacturing process. Subtle changes occur in materials after welding and heat treatment. By inspecting the hardness of the material and determining that it is correct is a major component of the inspection process and ensuring conformity.

Read More

Inspection Management Services

Inspection Management Services QA & QC Management

QA & QC Management

Inspection Management Services

Quality Programs:

• ISO based Quality Manual development

• Program deployment and training

• Program management services

• Chief Inspector services

• Vendor selection consulting

Inspection Programs

• Inspection Program Manual development

• Inspection Management software consulting

• Inspection planning utilizing prescribed, time-based, or risk-based inspection (RBI) strategies

• Inspection package development for on -stream/off-stream process assets, thickness surveys, conventional and advanced non-intrusive inspection and non-destructive examination (NDE) techniques

• Inspection scheduling, execution, recording, anomaly tracking, follow-up actions, maintenance notification, records and reporting

• Program deployment and training

• Program management services

• Vendor selection consulting

Read More• ISO based Quality Manual development

• Program deployment and training

• Program management services

• Chief Inspector services

• Vendor selection consulting

Inspection Programs

• Inspection Program Manual development

• Inspection Management software consulting

• Inspection planning utilizing prescribed, time-based, or risk-based inspection (RBI) strategies

• Inspection package development for on -stream/off-stream process assets, thickness surveys, conventional and advanced non-intrusive inspection and non-destructive examination (NDE) techniques

• Inspection scheduling, execution, recording, anomaly tracking, follow-up actions, maintenance notification, records and reporting

• Program deployment and training

• Program management services

• Vendor selection consulting

QA & QC Management

Quality Assurance Services

• Assistance in defining a QA program that meets the full scope of all regulatory requirements

• Perform monitoring, surveillance and QC of the work on behalf of client, to ensure contractors' quality programs are fully implemented and effective through review and acceptance of contractors' quality documentation (including inspection and test plans, procedures, quality records, final turnover documentation, etc.)

• Performing pre-award or pre-qualification surveys, including a complete review of the suppliers’ QA program to meet government or purchaser requirements

• Review of the design, specifications, drawings and specified standards to assure compliance with the applicable regulatory requirements

• QA of the organizations involved in the construction, manufacture and operation of your facility

Monitoring materials testing

• Inspection, witnessing or verification to establish the quality of a material, structure or system during manufacturing

• Factory acceptance tests of installations and equipment

• Pre-shipment inspections and loading supervision during the transportation phase

• Formal equipment audits at the premises of your engineering, constructor, manufacturer or sub-supplier – before and during manufacture

• Monitoring storage methods and preventive maintenance systems of plant equipment before and during installation

Read More• Assistance in defining a QA program that meets the full scope of all regulatory requirements

• Perform monitoring, surveillance and QC of the work on behalf of client, to ensure contractors' quality programs are fully implemented and effective through review and acceptance of contractors' quality documentation (including inspection and test plans, procedures, quality records, final turnover documentation, etc.)

• Performing pre-award or pre-qualification surveys, including a complete review of the suppliers’ QA program to meet government or purchaser requirements

• Review of the design, specifications, drawings and specified standards to assure compliance with the applicable regulatory requirements

• QA of the organizations involved in the construction, manufacture and operation of your facility

Monitoring materials testing

• Inspection, witnessing or verification to establish the quality of a material, structure or system during manufacturing

• Factory acceptance tests of installations and equipment

• Pre-shipment inspections and loading supervision during the transportation phase

• Formal equipment audits at the premises of your engineering, constructor, manufacturer or sub-supplier – before and during manufacture

• Monitoring storage methods and preventive maintenance systems of plant equipment before and during installation

Contact Us

Telephone: 780 665 4997

E Mail: info@ndtworx.com

Administrative Office:

10060 Jasper Avenue

Tower 1, Suite 2020

Edmonton, AB.

T5J 3R8